Building a Sustainable Future

Transforming recycled materials into beautiful, durable building solutions that respect our planet and enhance your spaces

Cradle-to-Cradle Commitment

We believe in creating products that give back to nature. Our cradle-to-cradle approach ensures every material has a purpose beyond its first life.

Design for Longevity

Our products are engineered to last 30+ years with minimal maintenance

Sustainable Materials

95% recycled content reduces environmental impact

Circular Economy

100% recyclable at end of life, closing the loop

Zero Waste Goal

Manufacturing processes designed to minimize waste

Closing the Loop on Sustainability

Our composite materials are designed for complete recyclability. At the end of their 30+ year lifespan, they can be reprocessed into new products, creating a truly circular economy.

From Inspiration to Global Innovation

Our story spans continents and cultures, combining Scandinavian design principles with innovative manufacturing to create a global leader in sustainable building materials.

2002

2002

The Idea

Where responsibility met curiosity

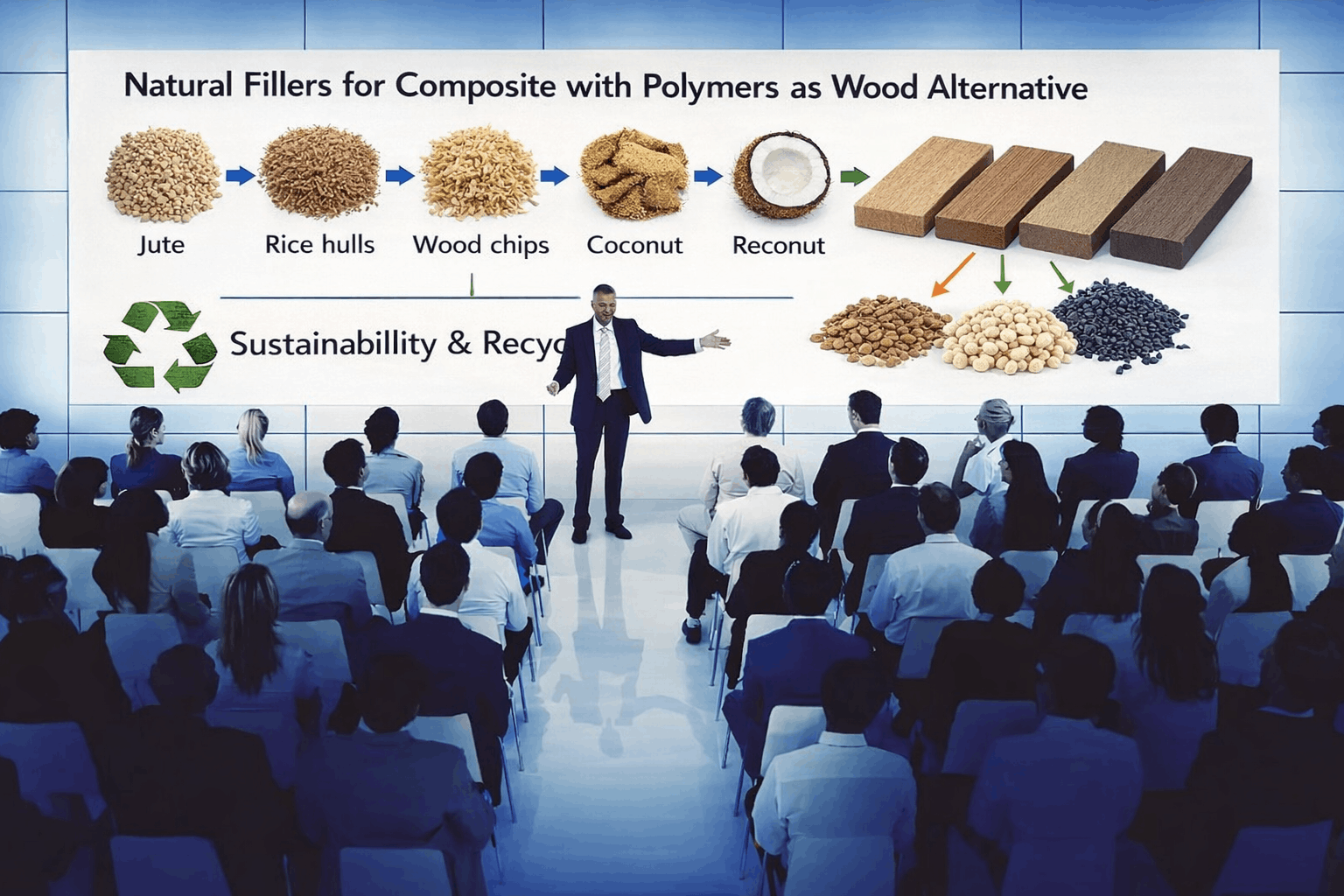

The idea behind Green Plank was born in Vienna during an international conference on eco-friendly composite materials as a sustainable wood-alternative.

One question stood out:

Why not use what nature already discards?

By combining natural fibers—such as rice hulls—with recycled polymers, the foundation was laid for a durable, low-maintenance, and environmentally responsible alternative to wood.

2003

2003

Learning Without Borders

Knowledge before scale

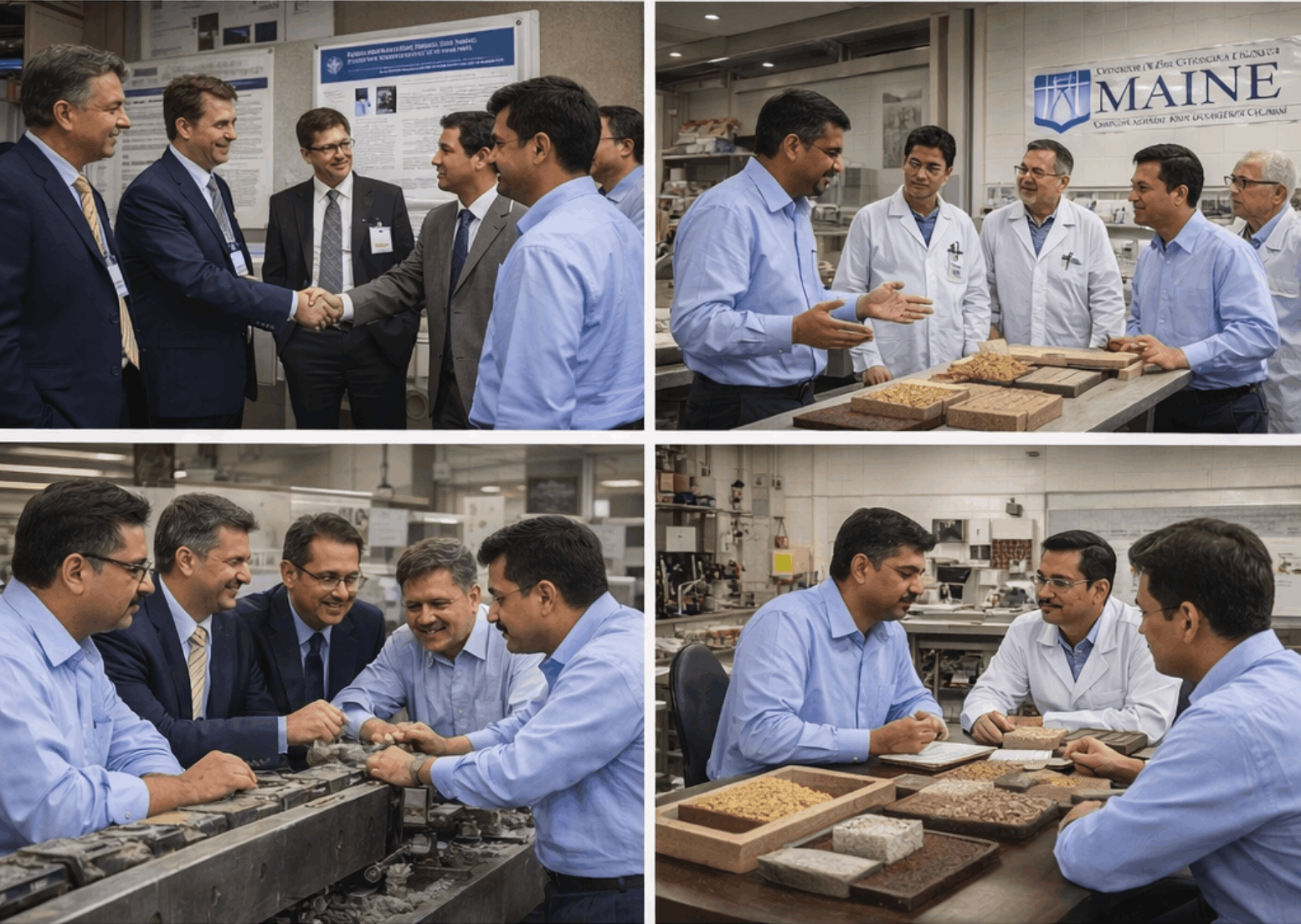

Through early conferences and global travel, Mr. Gill worked closely with material scientists, engineers, and extrusion specialists, including researchers from the University of Maine. This period was defined by learning—understanding fibers, polymers, formulations, and real-world performance.

2004

2004

From Knowledge to Reality

First production, European ambition

The acquired know-how was put into practice with the establishment of Asia’s first Natural Fiber Composite production facility in Lahore, using high-precision extrusion technology

At the same time, a family-owned company was founded in Malmö, Sweden—creating a direct connection to the European market and laying the groundwork for long-term Nordic presence

2005

2005

A Nordic Test

Entering a wood-loving region

Green Plank began exporting to Scandinavia—one of the world’s most forest-rich regions. The challenge was obvious.

Yet Scandinavian consumers and municipalities recognised the value of a durable, recycled, low-maintenance alternative that aligned with Nordic values of sustainability and responsible resource use.

A lasting foothold was established in Sweden and Denmark

2008

2008

Innovation Driven by Reality

Making durability accessible

Price remained a barrier.

Instead of accepting it, Green Plank redesigned the product.

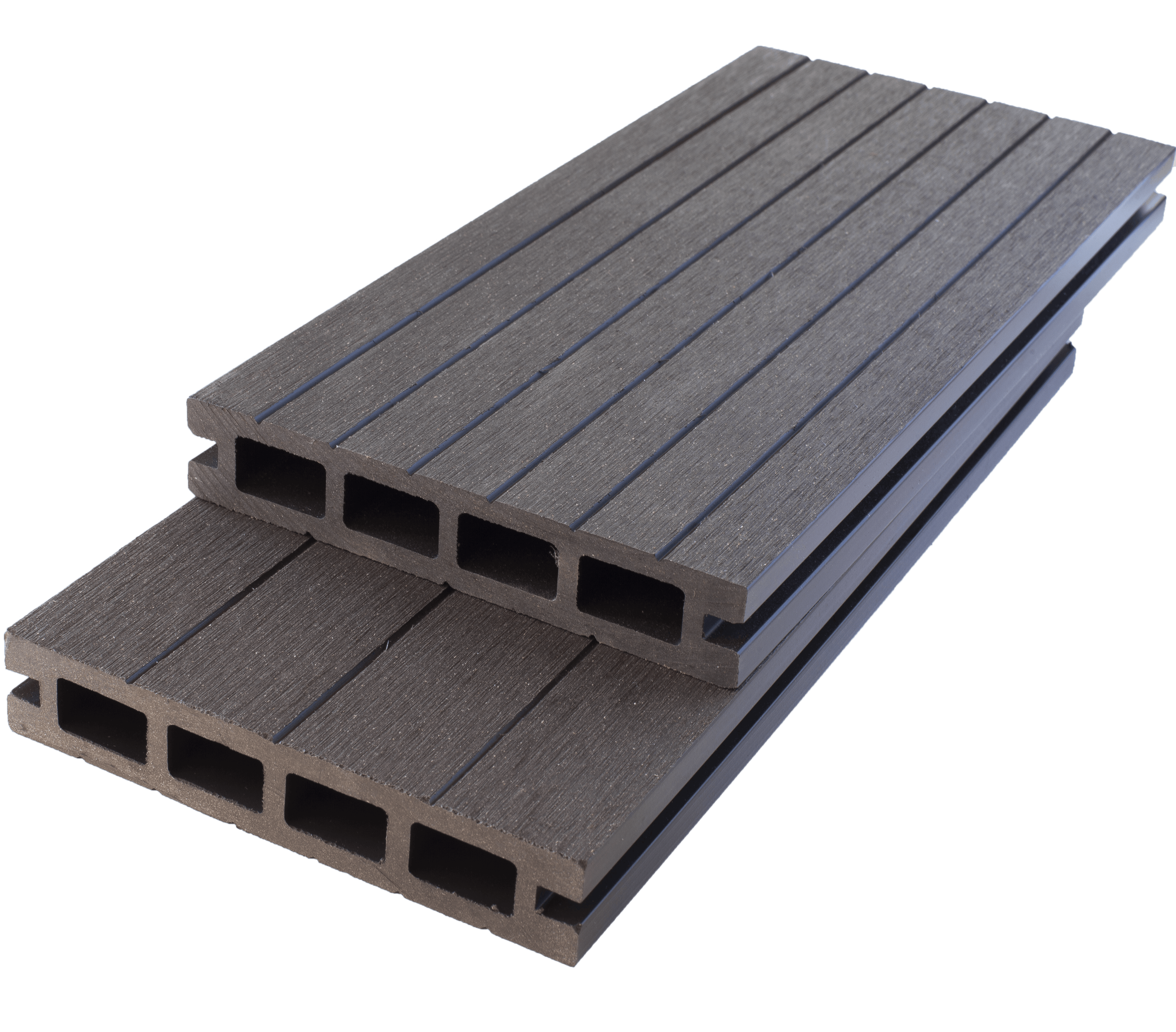

Hollow composite decking profiles were introduced—reducing material use without compromising structural performance. The result: lower cost, wider accessibility, and faster market adoption.

2011

2011

Design Meets Nature

A new surface expression

Green Plank introduced multi-colour composite planks, blending two to three tones for a more natural, living surface.

The concept was presented at DOMOTEX in Hannover—marking Green Plank’s first entry into the German and broader Western European markets

2013

2013

Beyond Decking

From surfaces to façades

Composite wall cladding profiles were launched at DOMOTEX, extending natural-fiber composite technology to building façades.

Durable, low-maintenance, and architecturally clean—Green Plank moved from outdoor flooring to complete exterior solutions

2015

2015

Recognition

Direction over scale

Green Plank was awarded Årets Nybyggare 2015 , presented by King Carl XVI Gustaf at The Royal Palace, Stockholm

By then, Green Plank had earned trust across Europe and the Middle East as a Swedish quality brand—defined by durability, responsibility, and long-term vision

The recognition was not about size.

It was about direction.

2019

2019

Innovation as a Discipline

Removing what doesn’t belong

Green Plank applied for its first Swedish patent:

a clip-free composite decking system with tongue-and-groove profiling

Designed to eliminate visible fasteners, prevent dirt and weed growth, improve surface stability, and simplify installation—innovation focused on everyday use, not complexity

2020

2020

A Strategic Shift

Turning disruption into clarity

Global supply chains collapsed during COVID-19. Borders closed. Production stopped.

Green Plank responded with a clear decision:

bring production closer to the market

The goal became clear—produce locally in Europe and sell globally, guided by Swedish quality standards.

2025

2025

A European Foundation

Designed in Scandinavia. Produced in Europe. Delivered globally.

Green Plank established its first European Natural Fiber Composite production unit in Klaipėda, Lithuania—under Swedish management and with skilled local technicians

The location offers efficient logistics, strong export access, and close proximity to European raw materials. Production follows Swedish quality standards and German precision technology.

Production follows Swedish quality standards, powered by German precision technology, combining discipline with engineering accuracy

Today, Green Plank is proud to supply the world with advanced natural-fiber composite solutions —

- Designed in Scandinavia

- Produced in Europe

- Delivered globally

- Made in EU

The journey continues—rooted in responsibility, guided by engineering, and proven over time.

Closer to the market.

Closer to responsibility.

Green Plank manufactures its natural-fiber composite products entirely within the European Union. A strategic choice to deliver reliability that global supply chains cannot guarantee.

100% EU Made

Quality & Precision

Lower CO₂ Footprint

Producing close to our markets significantly reduces transport distances and associated emissions.

Built for Municipal Trust

Ensures compliance with strict public procurement and environmental standards for cities.

Predictable Delivery

Shorter supply chains mean faster lead times and reduced dependency on global disruptions.

Full Traceability

European production enables full visibility from raw material sourcing to finished product.

Supporting Local Industry

Sustainability is also about people—investing in regional skills and strengthening EU know-how.

Quality Without Shortcuts

Strict environmental regulations and German precision technology ensure consistent performance.

"Green Plank’s decision to manufacture in Europe is about resilience, responsibility, and trust. Not because it is easy.But because it is right."

Quality Assurance System

Quality is not a promise.

It is a system.

Consistency is achieved through structure, not chance. Every Green Plank product is a result of a multi-national quality framework.

Swedish Management

Disciplined processes where production is defined, monitored, and continuously improved for long-term performance.

German Precision

Utilizing precision technology to eliminate variation in extrusion tolerances and material stability.

European Craft

Skilled local technicians who understand machines and materials to maintain quality on a daily basis.

Validated by Leaders

We work with accredited European research and testing institutions to validate product performance and safety. Testing is an ongoing process, not a one-time event.

RISE

SwedenResearch Institutes of Sweden

EPH

GermanyWood Tech Testing Lab

Ghent

BelgiumUniversity Laboratory

Euro-Accredited

EUStandard Compliance

Value Proposition

Documented Evidence

Performance verified by 3rd party labs.

Market Compliance

Exceeding European safety expectations.

Batch Traceability

Consistency across project cycles.

Quality at Green Plank is not about adding complexity.

It is about removing uncertainty.

Designed to last. Built to be trusted.

Wood Fibers & HDPE Composite

Our revolutionary composite combines natural wood fibers with high-density polyethylene (HDPE) to create a material that outperforms traditional wood in every way.

Wood Fibers (75%)

Recycled wood fibers provide natural aesthetics, texture, and strength while reducing deforestation

HDPE Plastic (15%)

Recycled high-density polyethylene ensures waterproofing, durability, and resistance to rot and insects

Additives (10%)

UV stabilizers and colorants ensure long-lasting beauty and protection against sun damage

The Perfect Blend

Natural beauty meets modern durability

Surfaces & Color Options

Choose from our premium selection of colors and finishes to perfectly match your aesthetic vision

Available Colors

Embossed Grain

Realistic wood texture for authentic feel

Capped Surface

Extra protection layer for enhanced durability

UV Resistant

Colors stay vibrant year after year

Simple Care Instructions

Enjoy beautiful outdoor spaces without the hassle. Our low-maintenance products require minimal care to stay looking great.

Regular Cleaning

Sweep debris weekly and hose down monthly

Spot Treatment

Remove stains immediately with mild soap and water

No Chemicals

Never requires staining, sealing, or painting

Annual Check

Inspect fasteners and replace if needed

Maintenance-Free Promise

Unlike traditional wood, our composite products never need staining, sealing, or painting. Save time, money, and enjoy your outdoor space worry-free.

Explore Products

Natural Weathering Behaviour

Understanding how your Green Plank® products age naturally over time in outdoor environments

What to Expect

Over time, exposure to sunlight and weather conditions will cause a natural color change in our composite materials. This weathering process results in a beautiful, silver-grey patina that enhances the wood-like appearance.

The rate of weathering varies based on geographic location, sun exposure, and environmental factors. Coastal areas with high salt content may experience faster changes compared to shaded or indoor installations.

Natural Patina

Beautiful silver-grey finish over time